Lean management is a concept that originated in the Japanese manufacturing industry in the year 1990. This began with the Toyota production system. Toyota was a small automobile manufacturer that later became a successful global business, and its operational process quickly caught on.

After the success of Toyota company, other companies started adopting similar methodologies, hoping to achieve the same level of success. Today, lean management is broadly used by leading businesses worldwide, including Nike and Intel.

Advantages of Lean Management

The goal of applying lean management methodologies by different companies is constant improvement. When you implement lean principles, they will help in achieving goals and save money and time. Apart from this, it also improves customer satisfaction and revenue from the repeat business.

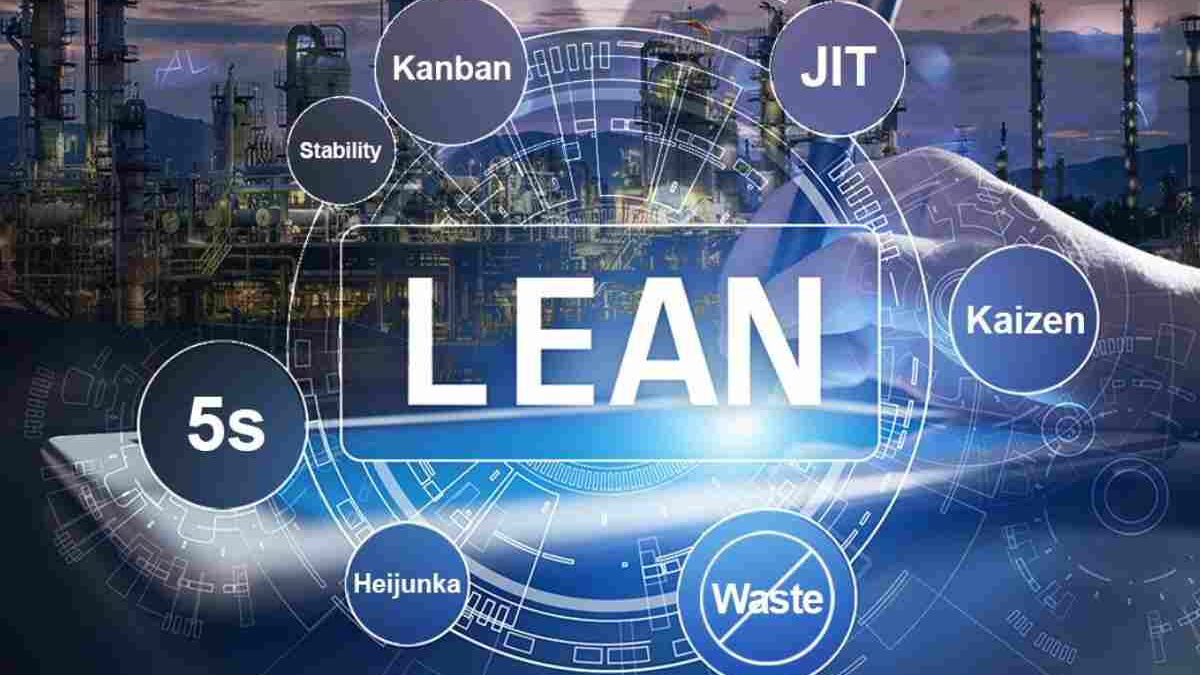

Lean management has various aspects, such as its application in manufacturing commerce services and general business rules. It will help avoid waste and eliminate it, improving overall business efficiency. Becoming proficient in lean management can be an invaluable investment.

Principles

Lean management has five core principles to help the process become more efficient and reliant.

Defining the value

This principle will help identify the product or service’s value from the customer’s perspective. It helps highlight the importance of creating and focusing on the timeline for the production process and delivery. This requires appropriately detailing staff requirements, prices, expectations, and other crucial information.

Mapping the value

This principle is also called waste mapping. It will help examine all the steps of any business process to understand which actions and resources can be removed to increase efficiency.

Establishing the flow

This principle will focus on attaining efficiency and ensuring that multiple operational tasks are completed as easily and quickly as possible without compromising quality.

Establishing the pull

In this step, you need to create a flow with enough material and resources to create the desired products on time and continuously.

Pursuing perfection

In this process or principle, the business of the industrialist needs to ensure that the above four principles work constantly, apart from this Ultimate lean mission.